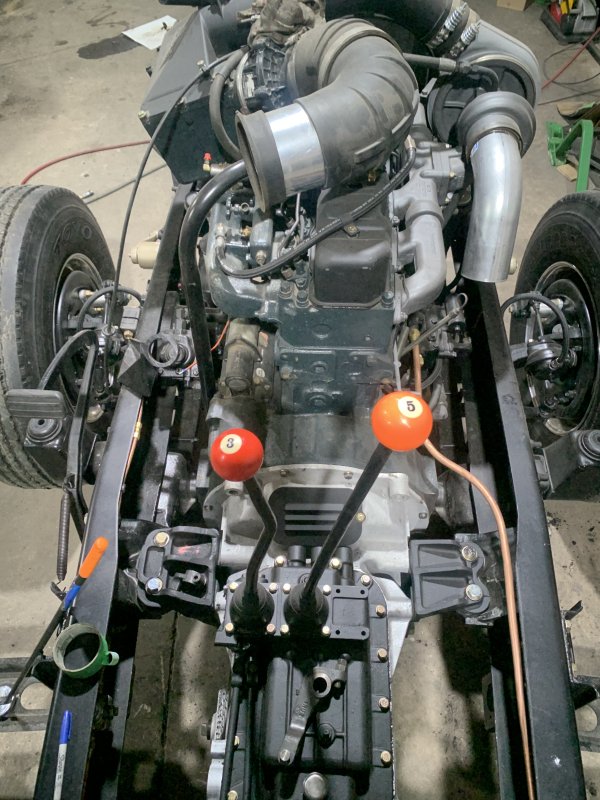

I got the trans installed and, of course, this time it bolted right in as it is the trans that came OUT of this chassis. Unfortunately, I had modified one of the clutch linkage levers to use on the other trans so now am on the hint for a replacement. I COULD re-cut and weld this one back to the way it was but will try to find an unmolested replay[cement and keep the re-cut weld option as a last resort. Interestingly, I took the shifter knobs off the 6 Spd to use on this triplex but, for some reason, one is 7/16" thread and the other 1/2". This trans are both 7/16". As much as I like the little original ones, rather than search for a replacement I decided to just make a couple pool ball knobs. My initial plan was to use the "6" and "1" since the truck is a B-61. Then I thought I would use the "9" turned over as a "6" with the "1" since they are the same colour and the yellow would go well with the metallic beige that will accompany the "black gold" on the cab. I then struck on, that I thought, a better idea. I will still make up the inverted "9" and "1" so I can swap them out from time to time for a change of scenery but, for now am going with what I settled on.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature currently requires accessing the site using the built-in Safari browser.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project "Gunsmoke"

- Thread starter licensed to kill

- Start date

Thanks. I can't explain. it (other than blame it on "OCD" but I just can NOT bring myself to reuse bolts OT use grade 5 anywhere. I LIKE the look of new grade 8's even when they will be under the cab and nobody will ever see them. I changed out all the oil pan bolts too new grade 8's as well. I guess if I run over a pedestrian they will see the nice shiny pan bolts as they go rolling under the truckCody. Looking neat and tidy. Good job!

My day started out kinda lousy so I abandoned the thought of doing anything that "matters" and , instead directed my attention to something that doesn't matter (yet). Got out my box of gauges to select which ones will be going into the dash, most are pretty old originals that SHOULD be cleaned up. One of my speedos had the needle broken off (how does that even happen???) so I thought, it is NFG anyways so I will see if I can get it apart and clean it and reset the OD to zero. Took a little cyphering but was able to get it apart, reset the OD and clean the face and lense AND get it all back together again. The lense on this gauge was pitted like someone was grinding near it so getting it "nice" was not in the cards. Was just a practice piece anyways. Since I want to clean ALL of the gauges, I will make some tools on the lathe for opening and closing the bezel for disassembly/reassembly. Turned out not too bad and was a relaxing way to spend the morning away from all the grunt work. There is SO much to do on this project that when I get frustrated (or bored) with one aspect I can "take a break" by just moving onto something else for awhile.

Great plan Cody, maybe even a life lesson….. “There is SO much to do on this project that when I get frustrated (or bored) with one aspect I can "take a break" by just moving onto something else for awhile.”

The problem of course is that I end up with suff half done all over the shop but I guess that is better than working on something when my heart isn't in it or just not doing anythingGreat plan Cody, maybe even a life lesson….. “There is SO much to do on this project that when I get frustrated (or bored) with one aspect I can "take a break" by just moving onto something else for awhile.”

OK, y'all failed the "test". Does anyone actually LOOK at the pics I post???. The "speedo" that I took apart and cleaned in post #84 was a tach but apparently nobody caught that. Just kidding. I looked back at my post and realized, for the first time that it was, in fact, a tach, not a speedo.......AND I TOOK THE THING APART,CLEANED IT AND PUT IT BACK TOGETHER. Talk about not paying attention. Could have have sworn it was a speedo.

It’s says engine revs..X 100000… alway thought it was X 1000

Never mind..just seen the RPM hundreds…

That "X100000" would be how the engine hours is calculated off the tach. The operating range of those engines is 1500-2100RPM and, @ X 100000, that would be using an average RPM of 1666. Not terribly accurate but I guess it is something of a guide. Don't think I have ever seen engine hours calculated off a tech before.It’s says engine revs..X 100000… alway thought it was X 1000

Never seen that before..don’t understand it…lol.

Been working on (more like struggling with) "gunsmoke" but have not posted as I have not done anything that anyone would find :"interesting". However, today, I cut three more holes in the gauge panel. I had to "move" the hole for the lighter as it would have been almost touching the lower right gauge so, for now, I just plugged it and will relocate it likely on the dash somewhere.

Plugging the lighter hole. (I cut out a plug and welded it first from the back, then from the front.

After welding I dressed it down. I knew I would Lose my marks for locating the new gauge holes so I predrilled them with a 1/4" bit first. (thought I was being smart)

Then, when I went to cut the hole with a hole saw, that damn light bracket was in the way so I had to mount the panel upside down nd cut the holes from the back. Thought, "no big deal, I have the centre holes already drilled" and off I went cutting the first hole

And.......it's about 1/16" high WTF!!!!. So I cut the other two (on the left) then proceed to "move" the first one to where it should be (by plugging the hole and recutting sort of).

Gauge holes are done. I will plug the hole fop the light switch (to the left of the lower left gauge) as it is too close to the gauge and relocate it, likely in line with the upper hole whereas Mack put it in line with the start button (lower left corner).

For reference for those unfamiliar with these trucks, they did not come with the two lower gauges on the left or the lower right gauge.

Plugging the lighter hole. (I cut out a plug and welded it first from the back, then from the front.

After welding I dressed it down. I knew I would Lose my marks for locating the new gauge holes so I predrilled them with a 1/4" bit first. (thought I was being smart)

Then, when I went to cut the hole with a hole saw, that damn light bracket was in the way so I had to mount the panel upside down nd cut the holes from the back. Thought, "no big deal, I have the centre holes already drilled" and off I went cutting the first hole

And.......it's about 1/16" high WTF!!!!. So I cut the other two (on the left) then proceed to "move" the first one to where it should be (by plugging the hole and recutting sort of).

Gauge holes are done. I will plug the hole fop the light switch (to the left of the lower left gauge) as it is too close to the gauge and relocate it, likely in line with the upper hole whereas Mack put it in line with the start button (lower left corner).

For reference for those unfamiliar with these trucks, they did not come with the two lower gauges on the left or the lower right gauge.