| 1961 PV544 Project - Update 8 |

This update deals with the cleanup of the front frame rails ("chassis legs" as called by Volvo), the firewall, dash and T5 transmission/bellhousing. While this cleanup was underway, it was still not clearly understood what the solution was going to be relative to front suspension/braking, etc. Overall, the desired outcome was to end up with a lowered car with disk brakes at the front (at least). It has been somewhat common practice to convert the front drums to the disk brake setup found on the 122 model. The conversion isn't difficult (after acquiring the necessary parts). Lowering the car utilizing the stock Volvo suspension is another matter - unless you want to simply cut or use smaller springs from another application. There is compromise with that solution. Since then, a completely different route has been selected and we'll get into that in the next article. |

Above: I started to scrape the seam area of the frame rail to determine how much cleanup was required. Like everything else so far, I found enough buried rust to justify stripping mostly everything off. |

Above: driver's side outer frame rail at toeboard. Just above the clutch pedal pivot you can see evidence of a previous repair. |

Above: to get at the entire area efficiently, I decided that the engine/transmission should come out followed by the front crossmember and steering column/steering box. |

Above: the Volvo B16 engine and M4 transmission out of the car. Despite our direction, this is a great powerplant and would be fabulous in something like a track T. This one's in great shape. |

Above: the front crossmember removed. This was quite simple requiring the removal of 8 bolts after it was disconnected from the steering box. |

Above: after scraping the outer side of the driver's side rail, I undid the column bracketry under the dash, removed the turn signal system and was then able to unbolt the steering box (getting the three steering box thu-frame bolts undone was a bit of a chore). The box and column assemby was then removed (not before I tilted it up out of the way and had the steering box fluid run back down and out the column into the car...). |

Above: Passenger side rail at toeboard and tunnel after initial cleanup and wipedown with solvent. You can see how Volvo integrated the rails into the unibody design. |

Above: same area but on driver's side |

Above: completed rails. At this point, I decided that I didn't need to take them to bare metal but would re-evaluate that later. As it turns out, it is just as well that I didn't. I really didn't need to go this far even. You'll see why in an upcoming article. |

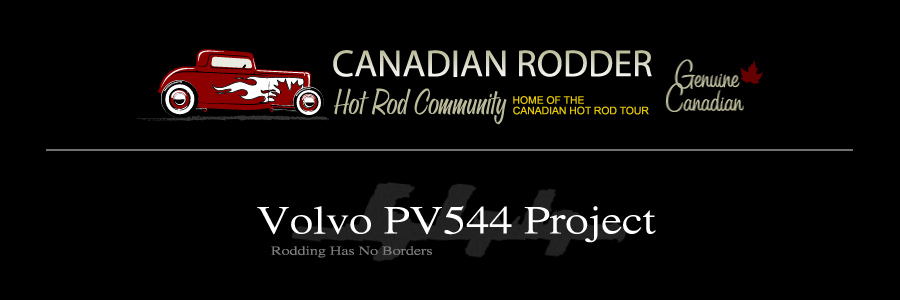

Above: the firewall as it was when I got the car. It had been painted when the car was painted (in the distant past) but was poorly prepped. I intended to remove the carb linkage bracketry and other protrusions so I decided to clean everything up and give it a sanding. |

Above: firewall after. |

Above: the dash as received. That's primer overspay on the dashpad and dash. The other half of the dashpad was missing so this hardly matters. |

Above: the left side of the dash as received. You can see here that the left side of the pad is missing. |

Above: as the steering column was out, I pulled off the balance of the pad and scraped then cleaned up the glue residue then removed the dash. |

Above: after dash removal. |

Above: I sanded-down and primed the area that the dash sits, stripped the dash ornamentation off, removed the switches then gave the dash a sanding. As the car was going to be moved, I reinstalled the dash and steering column as the front and rear suspension was going to be put back in to make it a roller. |

When I got to the location of the donor Blazer, the owner had removed the engine/transmission as a unit. We then proceeded to split the T5 and bellhousing from the engine. This is how it looked when I got it home. |

Above: the T5 after a fair bit of scraping, etc. The debris on the newspaper is oily sand. The red arrow points to the Borg Warner ID sticker which identified the T5 as a 13-52-145. Crossing this against the T5 reference chart yielded a 1986 S-truck application with gear ratios of 3.76, 2.18, 1.42, 1.00, .72. That made sense given what it was removed from. |

Above: after considerably more cleanup the T5 looked like this - clean enough to mock up with our engine. It will get a going-over from a transmission shop before final install. |

Above: similarly, I spent an afternoon and got the bellhousing looking like this. |

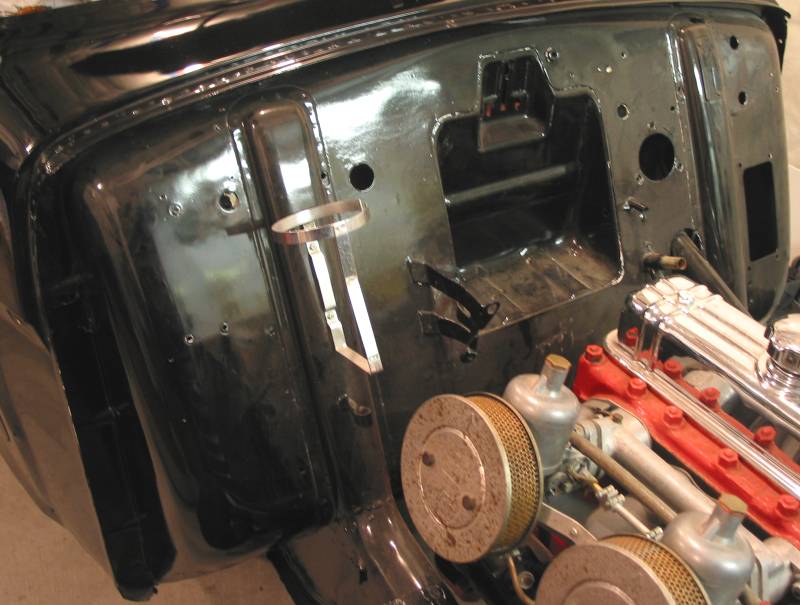

Above: I added the "Rodding Has No Borders" sentiment - My wife (Judy) felt it necessary to add the supplement it with another phrase from the Canadian Rodder archive. :) |

Above: After I reinstalled the front and rear suspensions and before I put wheels/tires back on it for transport and added the steering column, it looked like this. |

| Next: We move the car and begin with a strategy for suspension. |