Copyright

©

2000-2002 canadianrodder.com and

eFX Design and Communications.

All rights reserved

|

|

|

Early

Fabrication - Part 4

|

|

|

|

|

|

Let's talk about front and rear suspension treatments for our

project car. With a full-fendered car, our options increase for

a number of reasons but primarily because what you can get away

with looks-wise with a fendered car. To our eyes, a hiboy only

looks correct with an axle up front. At the rear, it's your choice.On

this car, we want ride quality, performance and good looks.

Up

Front

Having said that, and being that this is a '32 with a good view

of the front suspension inside those wide open front fenders,

we've opted for a dressed-up independent front suspension. We've

chosen one from Total Cost Involved. By dressed-up we mean that

most of the front end components are shiny - either polished or

plated. That is, upper and lower control arms, sway bar, ties

rod ends, etc. For brakes, we're going with polished 4-piston

Wilwoods. You'll see more of this front end as we progress.

In

the pictures that follow, you'll see the beginning of the installation

of these components.

|

| |

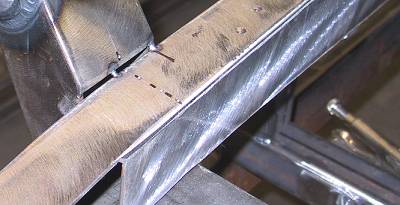

The

TCI front crossmember tacked into position. TCI provides detailed

The

TCI front crossmember tacked into position. TCI provides detailed

specification about locating the crossmember in the frame. By the

way, in

this photo, the motor was not in it's final resting place. |

| |

|

| |

In

this photo, you can see the matching of the centre line

In

this photo, you can see the matching of the centre line

on the suspension tower to the mark on the frame that has been

detemined by taking measurements per TCI instructions.

|

| |

In

The Rear

Out back, as you have already seen, the rearend will be located

by parallel 4-links. We'll add a panhard and sway bar. To control

rebound and suspend the car, we've decided to go with Air ride

Technologies' Shockwave 9000. The setup and geometry is very

similar to coilover setup in terms of the locating the Shockwave

unit.

The

9000 replaces a coilover by substituting a tapered airspring for

the coilspring while maintaining a centrally located shock absorber,

in this case, a high quality adjustable HAL billet aluminum unit.

The airspring is manufactured by Firestone.

The units are fed from a small tank which, in turn, is fed by

a small compressor. We'll feature more of these parts and the

installation after basic chassis details are completed. Use

the link in the left margin to visit Air Ride Technologies.

|

| |

In

this mock-up, the Shockwave unit is bolted to the Horton rear

4-link bracket

At the upper end, the unit is is being supported in the approximate

extended position.

The top mounting eye is higher than the horizontal frame plane

because the rear

crossmember, when installed, will be kicked up to allow the car

to sit lower.

|

| |

If

you're familiar with the Shockwave 9000, you'll notice that Air

RIde has redesigned

If

you're familiar with the Shockwave 9000, you'll notice that Air

RIde has redesigned

the top plate from a flat to a domed design. Slick looking unit. |

| |

|

| |

In

our next article, we'll show you more progess on the frame x-membering.

|

| |

|

| |

|

| |

|

| |

|

| |

|

|