The Big M

Active Member

Since it seems most folks here like to see build threads (with pics, of course) I thought I’d take the plunge and contribute mine. Progress has been slow for a variety of reasons, but here she is. My static display. My personal piece of garage art. The Merc:

Check out all its majesty!

It's coming up on 8 years since I first purchased this truck for the tidy sum of $250. But it's actually been more like a dozen years since I first laid eyes on it. It was sitting along Highway 11 near Girvin, Saskatchewan, and it wasn't alone. The story goes that it was originally owned by a man who had a plumbing business with his brother, and the two had matching trucks. Both red and white unibody Mercs. I vaguely remember that one of the two was a big back window, but at the time I had no idea what that meant (I’ve since realized it was a rare and desirable option). Since I was still a broke student at the time I just filed the truck away in my memory bank and moved on.

Fast forward to 2005. I was living in Swift Current, and I got a call from my friend. He had been trying to convince me for a while that I needed a project, even though I had no garage, no storage, and not even a driveway at the time! We had previously discussed what I would be interested in, and of course one option was a unibody Merc. So he called to tell me he had spotted one near Girvin. Red and white. The very same I had seen in 2000. My friend was even with me at the time we had first spotted it!

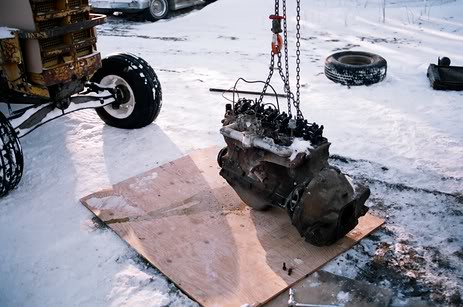

So the next weekend I drove out to take a look. She was rough!

As it turns out the second Merc had been purchased years earlier by someone who travelled up from the U.S. with a multi-car trailer. The seller said that both would have been gone if the guy had room for one more on the trailer. He also said he received offers of up to $375 for the tailgate alone, which he refused because he wanted to sell the truck complete. Lucky me!

Check out all its majesty!

It's coming up on 8 years since I first purchased this truck for the tidy sum of $250. But it's actually been more like a dozen years since I first laid eyes on it. It was sitting along Highway 11 near Girvin, Saskatchewan, and it wasn't alone. The story goes that it was originally owned by a man who had a plumbing business with his brother, and the two had matching trucks. Both red and white unibody Mercs. I vaguely remember that one of the two was a big back window, but at the time I had no idea what that meant (I’ve since realized it was a rare and desirable option). Since I was still a broke student at the time I just filed the truck away in my memory bank and moved on.

Fast forward to 2005. I was living in Swift Current, and I got a call from my friend. He had been trying to convince me for a while that I needed a project, even though I had no garage, no storage, and not even a driveway at the time! We had previously discussed what I would be interested in, and of course one option was a unibody Merc. So he called to tell me he had spotted one near Girvin. Red and white. The very same I had seen in 2000. My friend was even with me at the time we had first spotted it!

So the next weekend I drove out to take a look. She was rough!

As it turns out the second Merc had been purchased years earlier by someone who travelled up from the U.S. with a multi-car trailer. The seller said that both would have been gone if the guy had room for one more on the trailer. He also said he received offers of up to $375 for the tailgate alone, which he refused because he wanted to sell the truck complete. Lucky me!

Last edited: